Project Description

Polyamide

Polyamides belong to the most important thermoplastic materials. They are characterized by their high strength and stiffness, as well as impact strength and a good abrasion and wear resistance.

ABS

Chemical resistance and many positive mechanical properties (scratch-resistant, break-resistant, low weight, chemical resistance, etc.) are combined in the material acrylonitrile-butadiene-styrene, or ABS in short.

ABS is a low-cost mass-produced plastic whose features can be easily adjusted by mixing the components acrylonitrile, butadiene and styrene.

Softgrip

Thermoplastic elastomers – is named SOFTGRIP by us – are excellently suited to improve the haptics of surfaces or to generally make surfaces non-slip. By using the injection moulding process, all imaginable shapes can be created.

Here is where it gets hot!

At melt temperatures between 225 and 300° Celsius, we press thermoplastics into shape.

Whether small, medium or large series – we are the right partner for you!

Material

Thermoplastic

Surface

optical and functional

Color

individual

Fabrication

Injection molding

Products

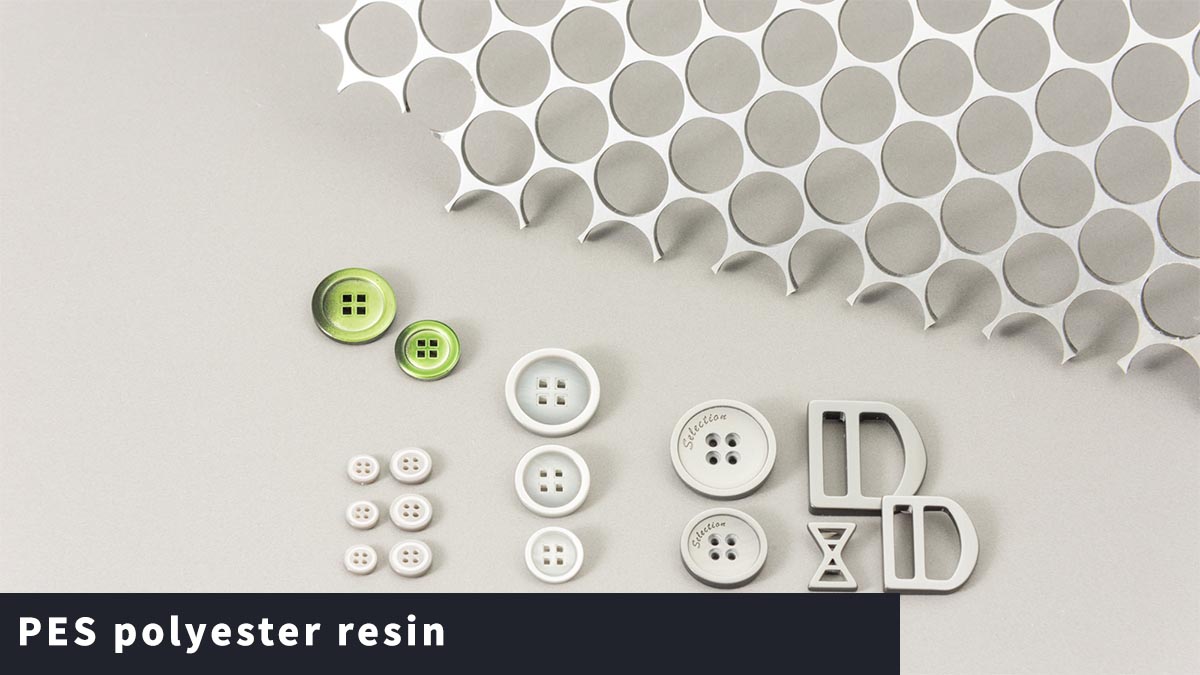

Company branding, opening buttons and eye buttons, cord stoppers and cord ends, zipper puller, patent buttons, push buttons and rivets, decorative trims, carabiners and clasps, toggles, belt buckles

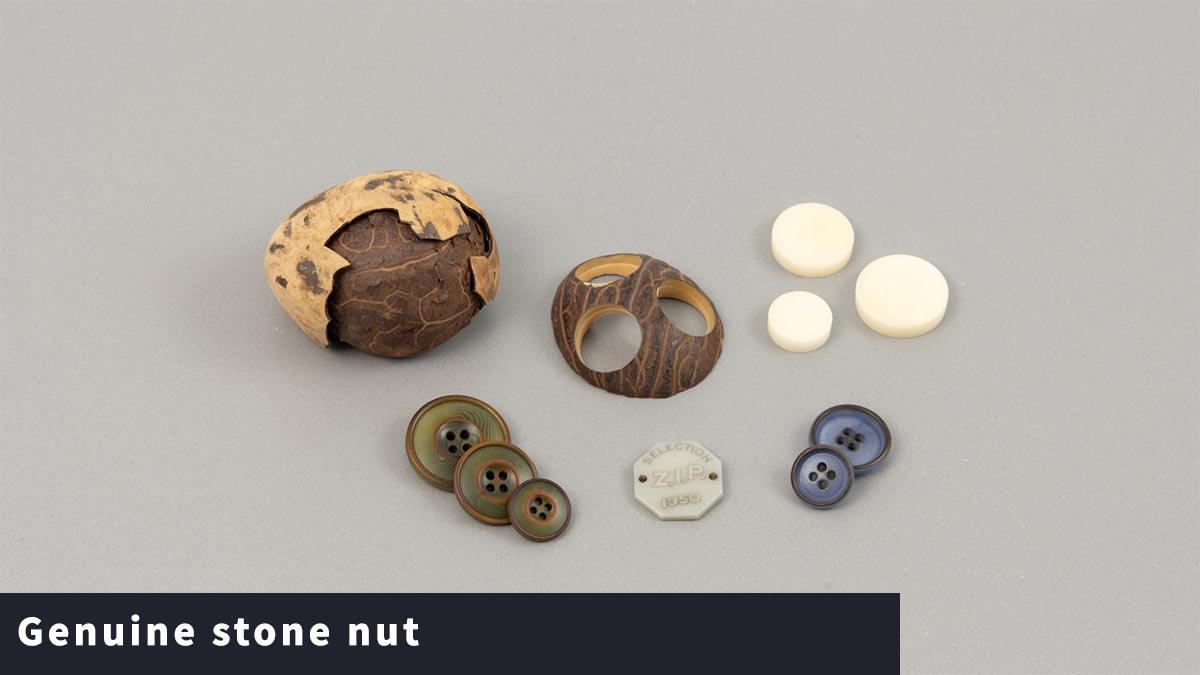

Other materials

Get in contact with us

You have a question or would like further information about our services and products. Then please contact us.

We will process your request as soon as possible.